It refers to the "cyclic" thermal expansion/contraction of piping as the system goes from one thermal state to another thermal state (for example, from "shut-down" to "normal operations" and then back to "shut-down"). Thermal Load (also referred as Expansion Load):

#Autopipe demo code

Two examples are presented to illustrate how piping can be supported by spring hangers and resting steel supports to comply with the code requirements for sustained loads. If pipe lifts up at any of the rod hangers / resting supports during operating condition, then that support does not carry any pipe weight and hence will not serve its purpose. Typical vertical supports to carry dead-weight are:īoth rod hangers and resting steel supports fully restrain downward pipe movement but permit pipe to lift up at such supports. Various international piping codes impose limits, also called "allowable stresses for sustained loads", on these axial stresses generated by dead-weight and pressure in order to avoid "failure by collapse".įor the calculated axial stresses to be below such allowable stresses for sustained loads, it may be necessary to support the piping system vertically. If the piping system is not supported in the vertical direction (i.e., in the gravity direction) excepting at equipment nozzles, bending of the pipe due to dead-weight may develop excessive stresses in the pipe and impose large loads on equipment nozzles, thereby increasing the susceptibility to "failure by collapse". On the other hand, dead-weight causes the pipe to bend (generally downward) between supports and nozzles, producing axial stresses in the pipe wall (also called "bending stresses") these bending stresses linearly vary across the pipe cross-section, being tensile at either the top or bottom surface and compressive at the other surface. These axial pressure stresses vary only with pressure, pipe diameter and wall thickness, all three of which are pre-set at the P&ID stage and hence these axial pressure stresses cannot be reduced by changing the piping layout or the support scheme. In addition, internal pressure develops axial stresses in the pipe wall. Internal design/operating pressure develops uniform circumferential stresses in the pipe wall, based on which pipe wall thickness is determined during the process/P&ID stage of plant design such that "failure by rupture" is avoided. Dead-weight is from weight of pipes, fittings, components such as valves, operating fluid, test fluid, insulation, cladding, lining etc. It mainly consists of internal pressure and dead-weight. Piping systems experience different loadings, categorized into three basic loading types, namely Sustained, Thermal and Occasional loads. Basic Pipe Stress Concepts for Piping Professionals Our Design and Detailed Engineering solutions and services are guided and managed by a team of experienced Engineering Management personnel.

SST provides the above solutions and services to EPC Contractors, Owner Operators and Engineering Consultants involved in the following fields.

#Autopipe demo software

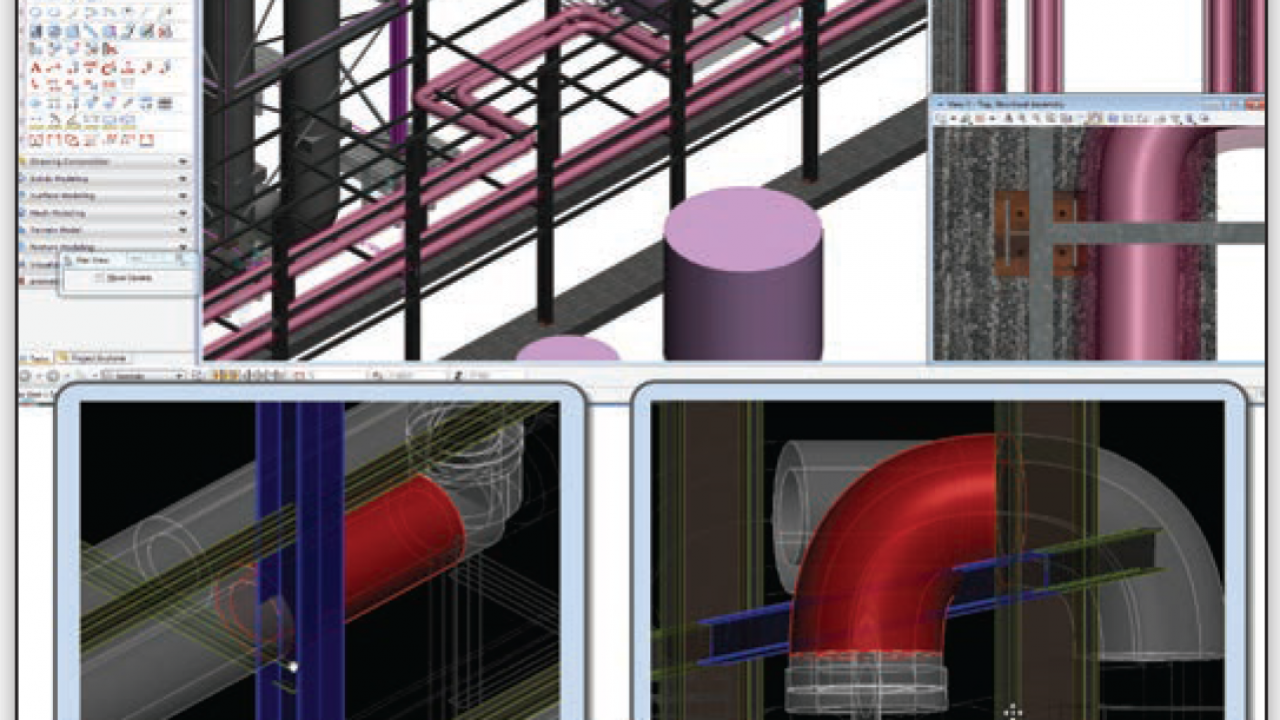

Piping Design Software such as checkSTRESS™ and HOTclash™.CAEPIPE™, Pipe Stress Analysis Software.Our Software Solutions offer flexibility to suit your business needs where they can be deployed in your premises or in the cloud. Here is a list of Software Solutions and Engineering Services currently offered.

Our fields of speciality are Piping Stress Analysis, Plant Layout, Piping Design & Engineering, and Information Management Software for Industrial Plants and Facilities worldwide. (SST), incorporated in the year 1983, is a premier provider of Software Solutions and Engineering Services.

0 kommentar(er)

0 kommentar(er)